Key Applications and Innovations in Joining Technologies

Welding, a fundamental process in manufacturing and construction, continuously evolves to meet the demands of modern industries. From intricate designs to large-scale infrastructure, understanding the diverse applications and ongoing innovations in joining technologies is crucial. This field encompasses a wide array of techniques and materials, allowing for the creation, repair, and modification of structures and components across numerous sectors, adapting to new challenges and material science advancements.

Joining technologies, with welding at their core, are indispensable across a multitude of industries, enabling the creation of robust and durable structures. These methods are not static; they are constantly refined through innovation, leading to more efficient, precise, and stronger bonds. The breadth of their application extends from the microscopic components in electronics to the massive frameworks of buildings and bridges, playing a critical role in daily life and industrial progress.

Custom Metal Welding Services and Specialized Fabrication

Custom metal welding services are vital for projects requiring specific designs, unique material combinations, or specialized structural integrity. These services cater to a diverse clientele, including artists creating sculptures, engineers developing prototypes, and businesses needing tailored machinery components. Custom fabrication often involves working with a variety of metals such as stainless steel, aluminum, brass, and exotic alloys, each requiring particular welding techniques and expertise. The precision and skill involved ensure that the final product meets exact specifications, whether for aesthetic purposes or high-performance industrial applications. This area of welding demands a deep understanding of metallurgy and an ability to adapt techniques to suit individual project requirements.

Residential Welding Repairs and Home Improvement Projects

For homeowners and local businesses, residential welding repairs offer practical solutions for maintaining and enhancing properties. This can include repairing broken gates, fences, handrails, or outdoor furniture. Such services also extend to reinforcing structural elements, mending vehicle frames, or customizing metal fixtures around a home. The convenience of local services that can address these needs helps preserve the value and functionality of residential assets. Often, these repairs require mobile welding units that can perform work on-site, providing flexibility and efficiency for property owners in your area.

Industrial Steel Welding Work and Infrastructure Development

Industrial steel welding work forms the backbone of heavy construction, manufacturing, and infrastructure projects. This sector involves welding massive steel structures for buildings, bridges, pipelines, and industrial machinery. The demands are high, requiring stringent quality control, adherence to safety standards, and the use of advanced welding processes capable of handling thick materials and challenging environments. Innovations in this field focus on increasing efficiency, improving weld quality, and ensuring the longevity of critical infrastructure. Automation and robotics are increasingly being integrated to enhance precision and speed in these large-scale operations, contributing significantly to modern industrial development.

Advancements and Accessibility in Welding Project Kits

Innovations in welding extend beyond industrial applications to make the craft more accessible to enthusiasts and learners. Welding project kits offer a structured way for individuals to learn basic welding skills and complete practical projects. These kits typically include pre-cut metal pieces, instructions, and sometimes even consumables like welding rods or wire. They serve as an excellent entry point for hobbyists or students interested in metalwork, allowing them to gain hands-on experience with various joining techniques in a controlled environment. The availability of such kits reflects a broader trend towards democratizing technical skills and fostering creativity in metal fabrication.

Understanding Typical Welding Service Cost Estimations

When considering welding services, understanding potential costs is important. These estimates can vary significantly based on the complexity of the project, the type of metal, the specific welding process required, and the welder’s experience and location. Small, straightforward repairs might involve a minimum service fee, while larger, custom fabrication or industrial projects are often quoted based on material costs, labor hours, and specialized equipment usage. Researching local service providers and obtaining multiple quotes can help in budgeting for welding needs.

| Service Type | Description | Estimated Cost Range (USD) |

|---|---|---|

| Small Residential Repair | Gate latch, minor fence repair | $75 - $200 |

| Custom Metal Art Fabrication | Small to medium artistic piece | $200 - $1,000+ |

| Structural Steel Welding | Per linear foot for beams/columns (industrial) | $20 - $50+ |

| Mobile Welding Service | On-site repair, hourly rate + travel | $100 - $150 per hour |

| Specialized Alloy Welding | Stainless steel, aluminum, exotic metals | $150 - $300+ per hour |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

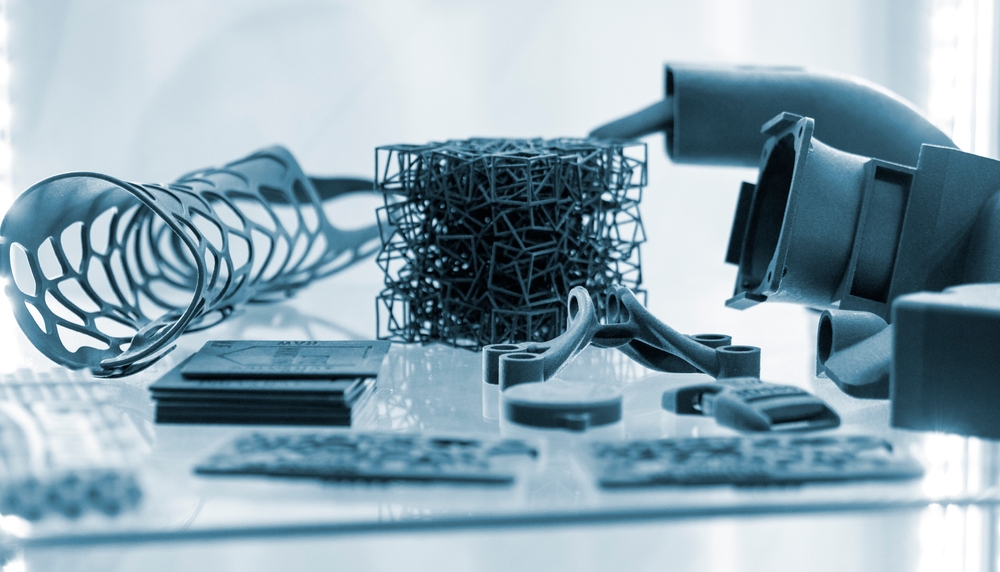

Future Directions and Sustainability in Joining Technologies

The future of joining technologies is focused on sustainability, efficiency, and advanced material integration. Research continues into additive manufacturing techniques, hybrid welding processes that combine different energy sources, and methods for joining dissimilar materials with greater strength and reliability. These innovations aim to reduce material waste, lower energy consumption, and enable the creation of lighter, stronger, and more complex structures. The ongoing evolution ensures that welding and other joining methods will remain at the forefront of technological advancement, adapting to new materials and environmental considerations.

Welding and joining technologies are dynamic fields that underpin countless aspects of modern life, from the smallest household repairs to the largest industrial constructions. The continuous development of new methods, materials, and applications ensures that these essential processes will continue to evolve, meeting future demands for strength, precision, and efficiency across various sectors. Understanding these applications and innovations highlights the critical role welding plays in shaping our built environment and technological capabilities.